Rotational Molding: The Process in Detail

Rotational molding can be a method that has been around for over fifty years. It enables manufacturers to produce plastic-type parts with incredible depth, employing a lot fewer uncooked supplies than traditional processes. In the following paragraphs, we will experience rotational molding from beginning to end and go over how it operates.

Molds are set up simply by making an shot-shaped product or sculpture away from clay or wax (or other smooth modeling moderate). The done product is then given metallic layer so that when heated up, it does not melt during manufacturing. Plastics are injected in to these molds at higher-pressure costs in which they amazing and harden right away as they enter into the sprue entrance on the way towards turning into molded items that are then ejected from the mold.

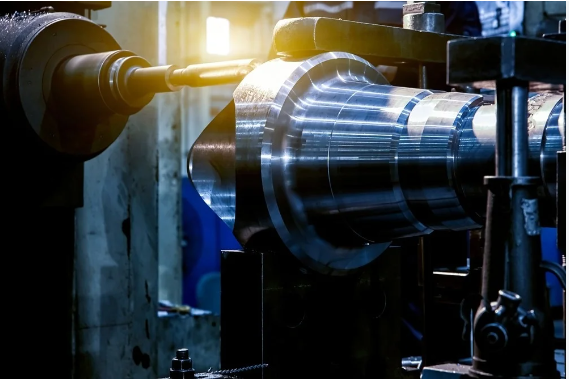

When plastics enter in a rotational molding unit, these are warmed up as much as about 270 degrees Fahrenheit and injected in to a metal-lined cylinder with chilly normal water from all instructions at substantial costs (around 100 gallons a minute).

The plastic-type goes into through a entrance referred to as the “sprue,” which can be hooked up by hoses to a extruder head that injects or combines thermoplastic pellets to allow them to be rapidly cooled off and shaped. The revolutions within these cylinders build a vacuum result as molten plastic-type cools down off over alone mainly because it does not have any oxygen bubbles to cause cooling opposition. This permits for much faster manufacturing times during the done products.

Rotational molded pieces can be accomplished with numerous types of ultimate looks. Rotational Molding is how plastics can be created to search like metallic, window, and even rubberized. The detail that could be duplicated on each mold is near unlimited due to rotational molding’s ability to create incredibly sophisticated elements in one go.

The rotational molding method is incredibly adaptable and can be used various items, including furniture or large components like car bumpers. It’s also productive–consuming about 90 moments to produce 120 pieces each hour.